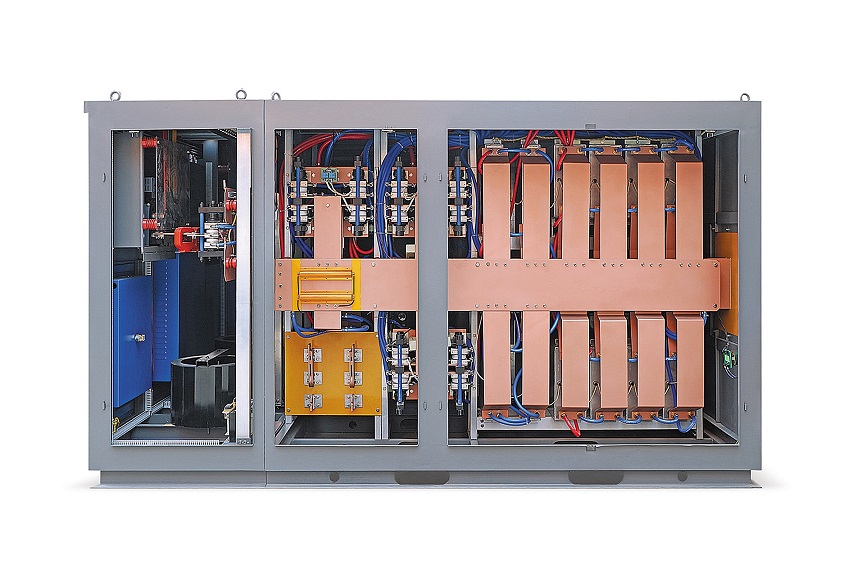

① Imported high-pressure carbon-free hose and 304 stainless steel clamp: durable!

② Optical fiber transmission inverter trigger pulse signal plate: a strong ability of anti-interference and stable operation!

③ The high-quality heavy platform Thyristor, square-type water cooling radiator (Hengyang Patent No.): more convenient!

④ Customized capacitor: horizontal structure, safer insulation outer shell. The high-strength magnesium-aluminum alloy makes the product more anti-corrosion and more durable.

⑤ Conductive copper bar: Large and thick copper can reduce heat loss and save energy! With a copper sandblasted surface and anti-oxidation coating, the contact surface of the copper bar is more conductive and the color does not fade which makes the product more beautiful!

⑥ Isolation (exchange) switch: when the furnace is replaced or overhauled, it is possible to control the power failure of one furnace without affecting the normal operation of the other furnace. The design is humanized.

⑦ Plate heat exchange system (Hengyang Patent No.): It can ensure the cooling water temperature in the equipment and prevent the external hard water from entering the power, which can minimize the equipment failure.