Product Category

Cast steel melting furnace

Category:

Parameters

Other Recommendations

Product Description

Overview and purpose

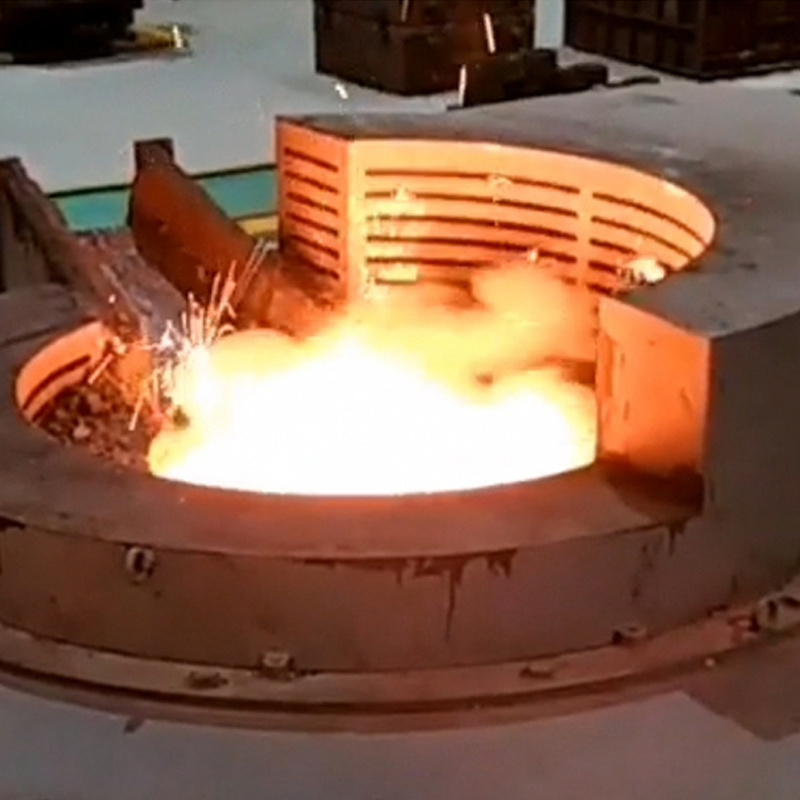

Medium frequency furnace is a frequency conversion device that converts three-phase power frequency current into single-phase medium frequency current. It induces eddy current loss in metal through electromagnetic field induction, achieving the purpose of heating and melting. Used for melting black or non-ferrous metals and alloy materials such as steel, copper, aluminum, etc; Mainly used in the casting and steelmaking industries!

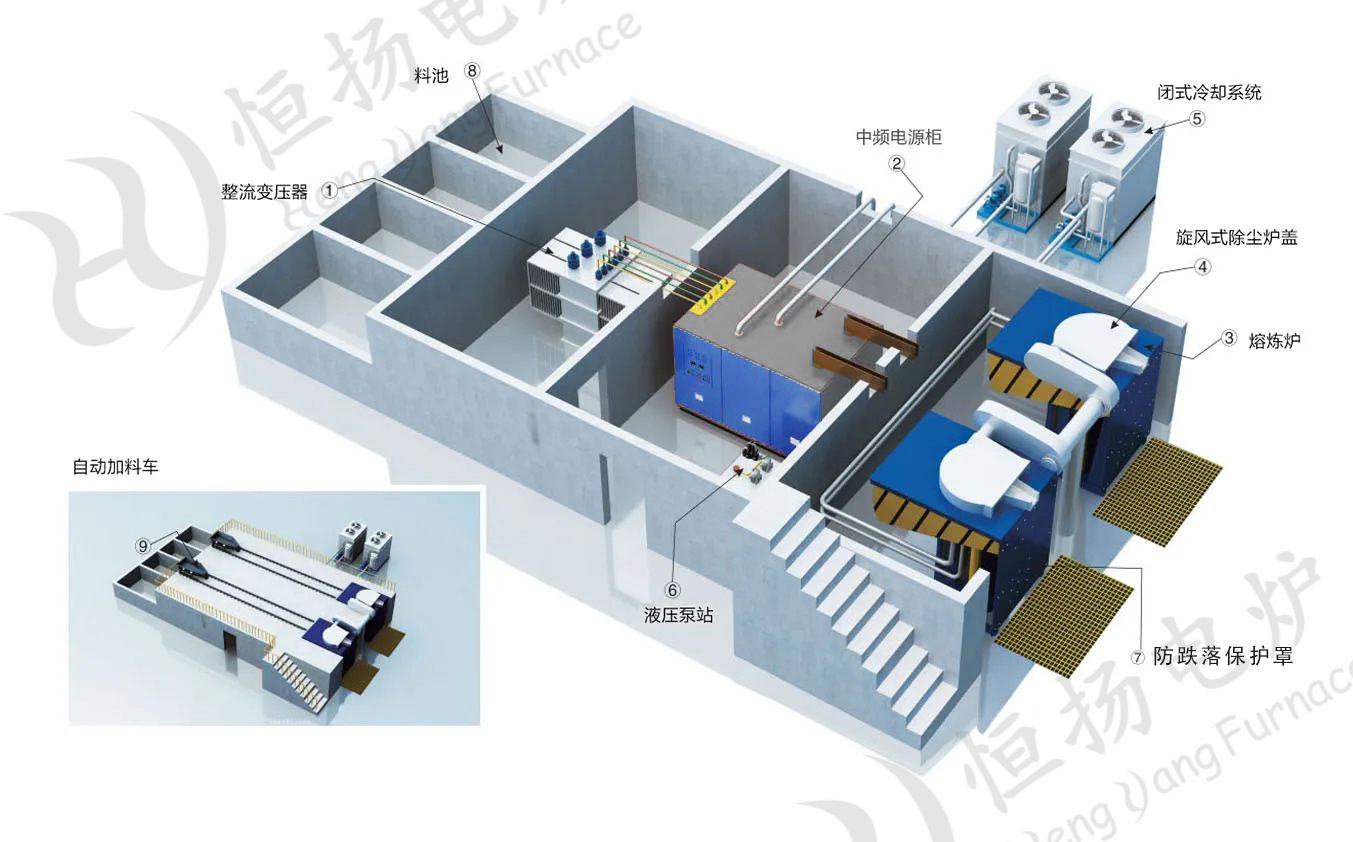

We can provide complete equipment production lines for foundry manufacturers, including melting systems, cooling systems, dust removal systems, automatic batching and feeding systems, and pouring systems.

The diversification of products and different cost-effectiveness provide you with more choices and experiences.

1、 Characteristics of Hengyang Power Intelligent Manufacturing

This equipment can achieve fully automatic remote control, including PLC programmable controllers, HMI human-machine interfaces, industrial control computer systems, industrial control configuration software, and various sensors. It can achieve automated operations such as automatic temperature control, automatic baking, and anti piercing furnace alarm, making it safer and more convenient to use!

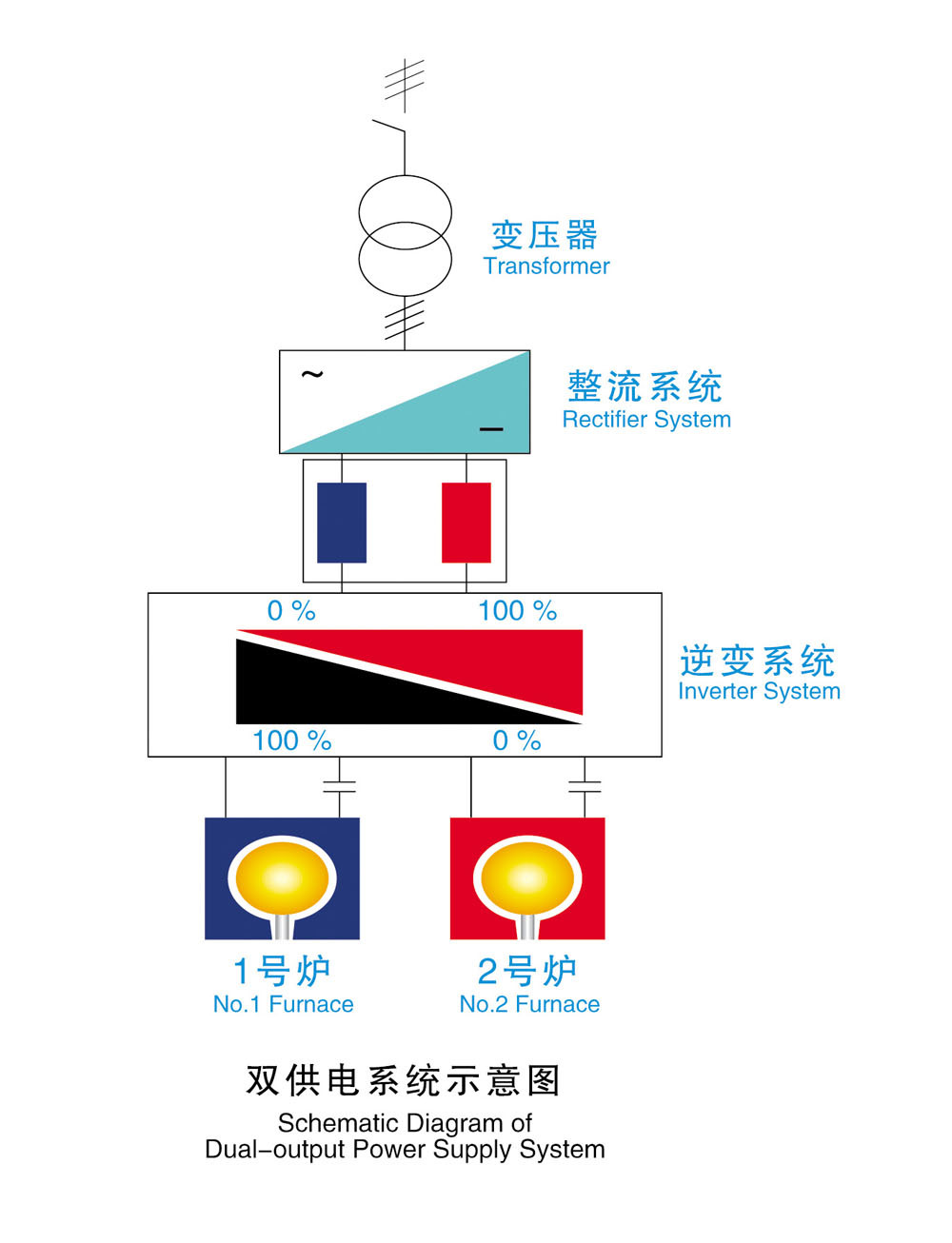

★★★ Efficient and energy-saving series one to two (one furnace melting and one furnace insulation) dual power supply design

Series connected intermediate frequency power supply can achieve single power supply, dual power supply, and multi power supply configurations

The new type of one to two series intermediate frequency melting furnace has the function of using a set of intermediate frequency power supply to simultaneously operate two furnace bodies. The equipment utilization rate reaches 100%. By adjusting the power knob (or digital operation screen), the total power of the intermediate frequency power supply can be distributed and used between two furnaces, achieving the effect of melting one furnace and keeping the other warm. It can achieve one-time casting of large castings or provide continuous supply of molten iron to the production line. The continuous and uninterrupted melting mode greatly improves production volume, is energy-saving and practical, and has been widely accepted and loved by customers.

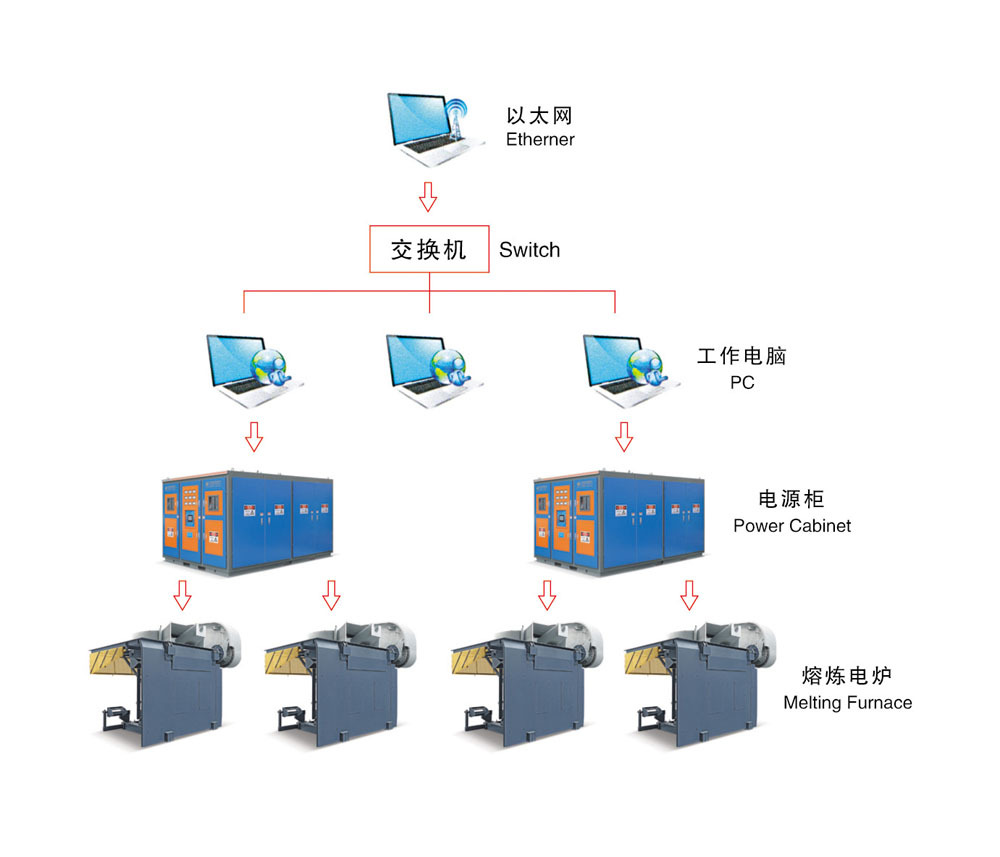

★★★ Advanced computerized melting management system

The on-site smelting management computer, digital main control board, and PLC equipment form a network system. It can be controlled and managed in the office through switch expansion. Equipped with Ethernet and USB ports, as well as a unique IP address, it enables data collection, transmission, and monitoring of devices from anywhere in the world, providing remote diagnosis and quick and timely troubleshooting.

★★★ Fully digital on-site melting control system

It can achieve automated operations such as automatic temperature control, automatic oven drying, power distribution display, intelligent melting management, and display and storage of fault information.

This set of equipment can be fully controlled automatically, including PLC programmable controllers, HMI human-machine interfaces, industrial control computer systems, industrial control configuration software, and various sensors. It can be configured with foundry equipment and operations, and connected to various tools, including remote displays, temperature measuring instruments, thermal analyzers, spectrometers, demand controllers, and large screen displays. Safer and more convenient to use!

★★★ Remote control console

When the intermediate frequency power cabinet is placed in the basement and the remote control console is placed on the furnace platform, other functional operations such as starting, stopping, and resetting of the intermediate frequency power supply can be achieved. The remote control panel is equipped with a large-sized touch screen, PLC, and human-machine interface to form a convenient on-site melting manager. Its functions include automatic furnace drying, cold furnace start-up, fault diagnosis, fault information display and storage, operation information display, system status display, etc.

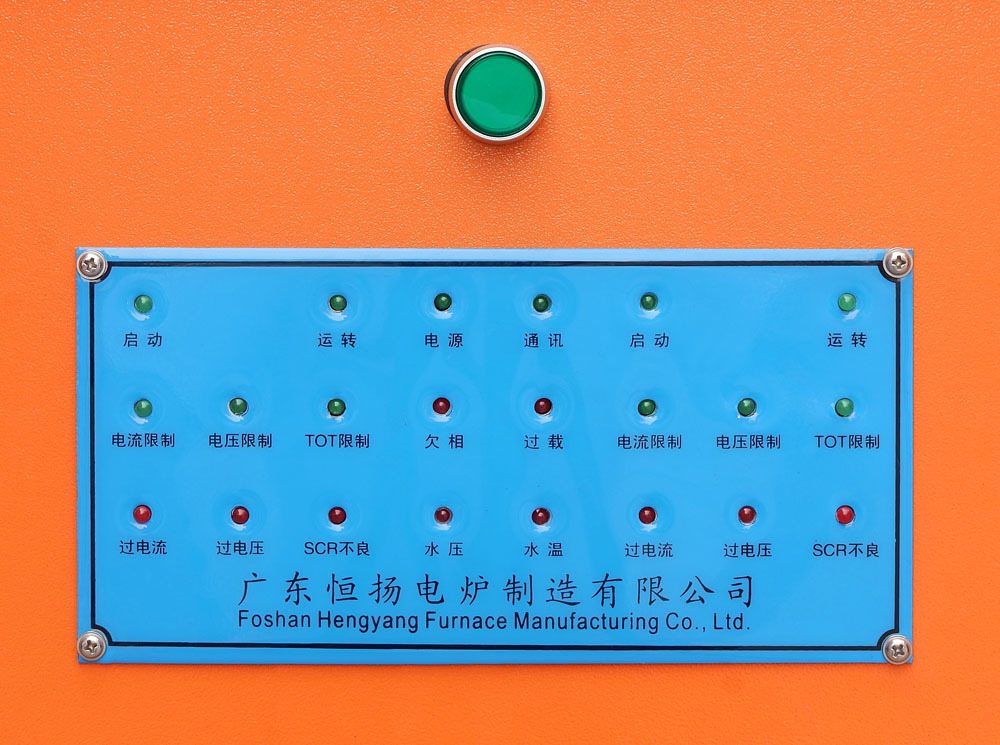

★★★ Fault detection (protection) display

Real time tracking and protection of running equipment in all directions. When abnormal values such as load short circuit, overcurrent, overvoltage, insufficient water pressure, and high water temperature are detected, they will be promptly fed back to the control system to achieve automatic shutdown protection and prevent accidents before they occur. In addition, damaged components such as thyristors, compensating capacitors, and voltage transformers will automatically shut down and light up corresponding indicator lights.

2、 Characteristics of Hengyang Electric Furnace Intelligent Manufacturing

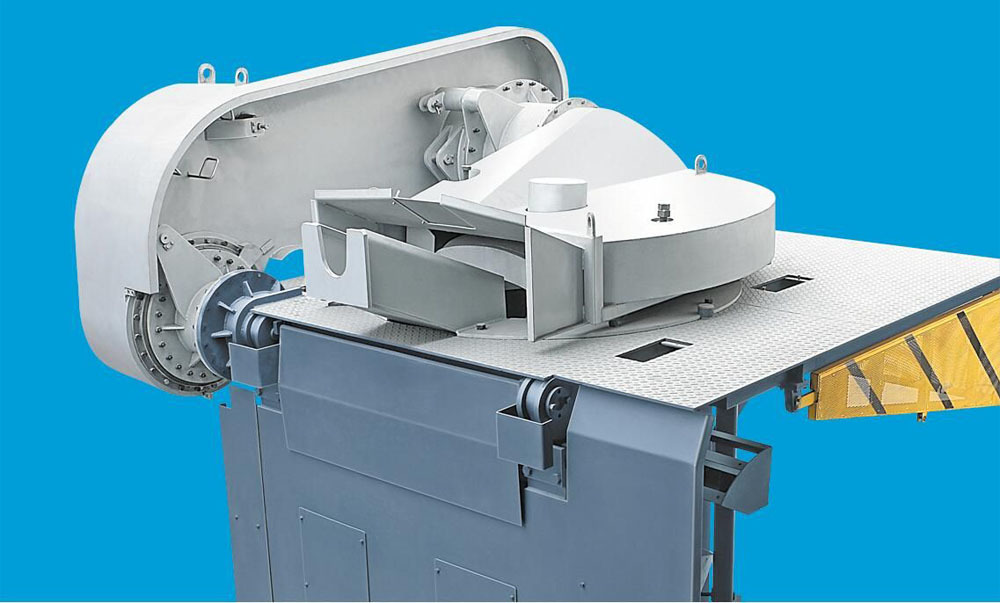

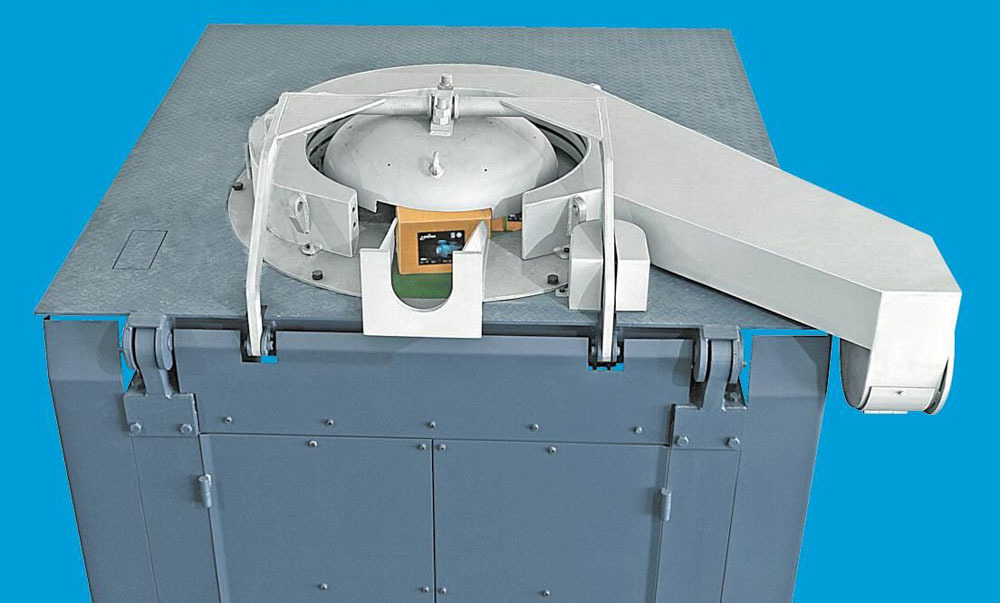

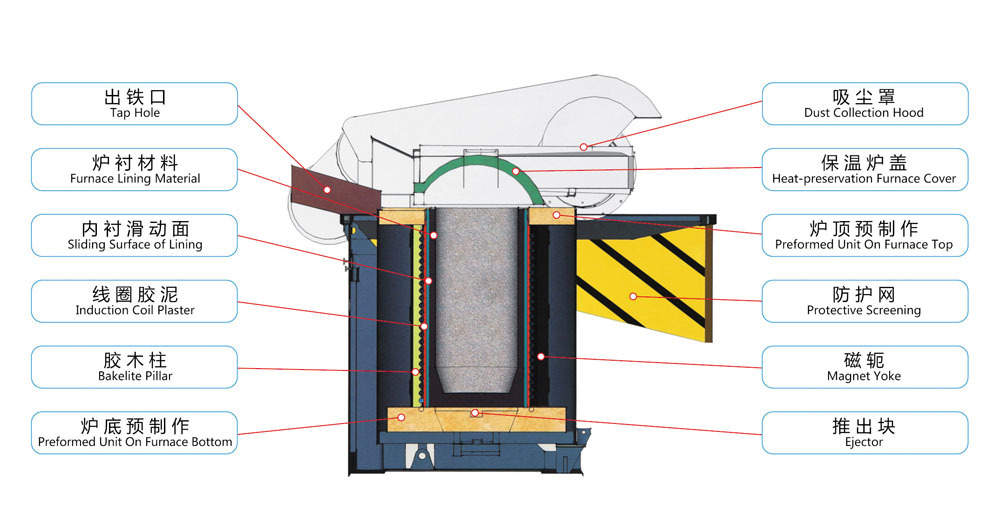

1. The design of the intermediate frequency coreless induction furnace body includes two dust removal systems: a dust hood and a dust ring

The vacuum hood (ring) absorbs dust and exhaust gas generated during smelting through a certain amount of air flow, achieving and improving the emission effect of exhaust gas. It is designed in accordance with environmental impact assessment requirements, and users can choose the configuration according to their needs.

Characteristics of whirlwind and side suction environmentally friendly dust removal and insulation furnace covers

|

|

| Whirlwind style vacuum hood: It has excellent vacuuming effect, occupies less space, and can be tilted back and forth and operated to stay in any position. Suitable for fully automated feeding and discharging operations in foundries | Side suction vacuum ring: Compared to the cyclone type, the design has: no forward and backward tilting motion mechanism, simple installation, suitable for semi automated or manual feeding in foundries where vacuum hoods cannot be used due to certain feeding methods Discharge operation |

2. Fully intelligent automation and humanized functional design

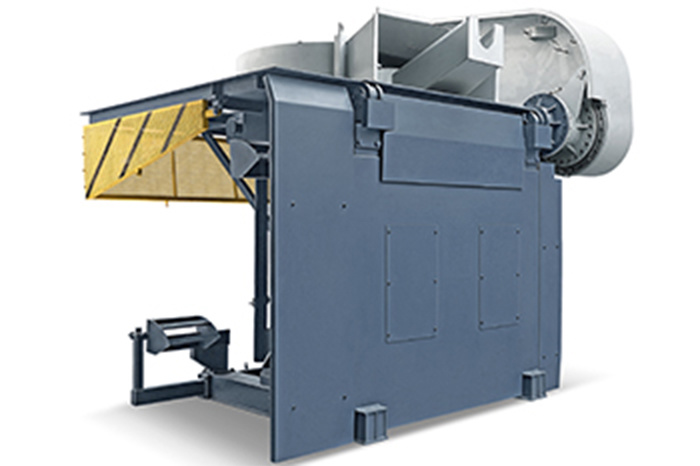

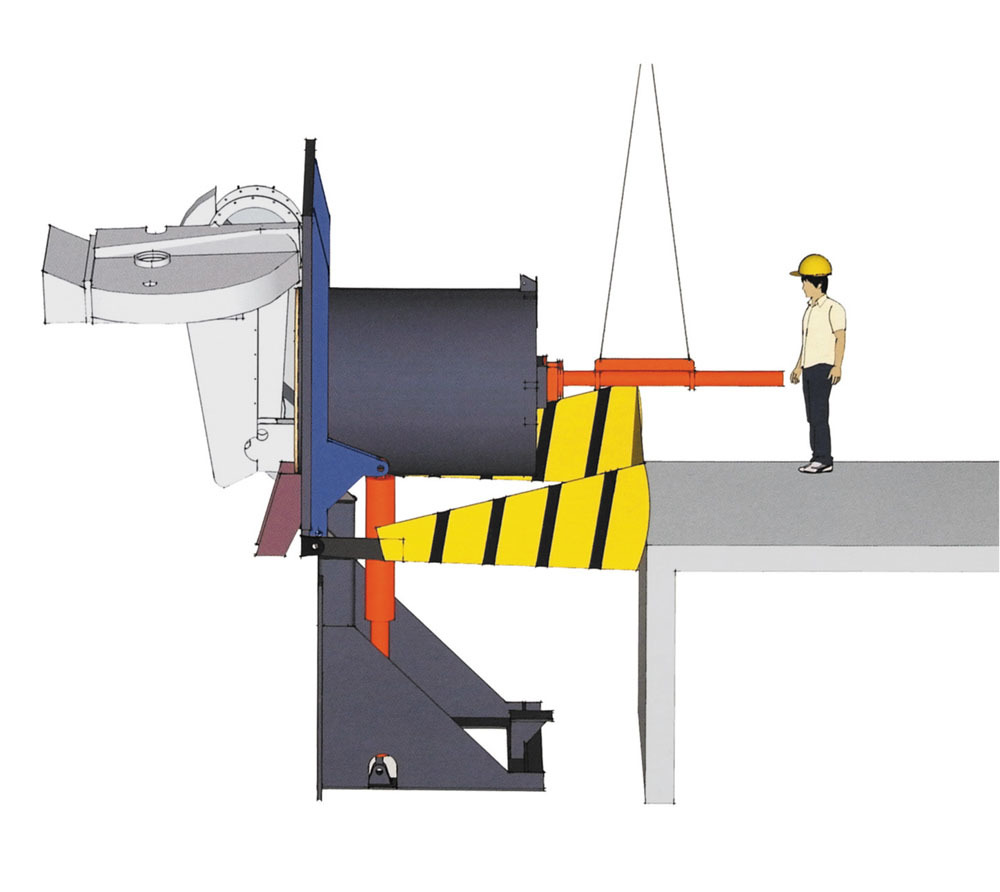

★ Tilting furnace oil cylinder system: including hydraulic pump station and tilting furnace operation platform. Designed for full load tilting of the furnace, it consists of a hydraulic pump and drive motor, emergency pump, motor starting device, oil tank, return oil and oil suction filtration device (with explosion-proof valve device). The tilting, stopping, and resetting of the furnace body are achieved through the buttons and handles on the hydraulic control panel. The furnace body can be tilted 95 degrees by the hydraulic cylinder, pouring out all the molten metal, and can be stopped at any position during the tilting process as needed.

★ Automatic constant temperature function: The required range of furnace water temperature can be pre-set, and one click start can achieve automatic constant temperature; Compared to traditional manual temperature control, the automatic constant temperature function saves time and effort, is more sensitive and accurate, makes it easier to control the furnace water temperature, reduces oxidation and burning losses, and ensures even metal composition for better product quality during casting!

★ Automatic oven drying function: Oven drying is a relatively complex and long-term curve heating process. To extend the service life of the intermediate frequency furnace and reduce production costs, the correct furnace building and drying process is crucial. Our company's innovative automatic baking function can pre-set the required time and temperature for different baking stages based on the baking temperature requirements of different refractory materials for the furnace lining; According to the pre-set time and temperature values of the PLC, one key start is used to automatically match and continuously adjust the size of the intermediate frequency power, control the heating speed, prevent cracks in the furnace lining, and achieve the goal of automatic curve baking. It not only avoids manual errors but also reduces the labor time and intensity of workers.

★ Anti piercing furnace alarm function: Hengyang's unique dual anti piercing furnace alarm function adopts a dual combination of differential current and DC injection detection. Provided extremely reliable and comprehensive rapid protection for furnace leakage and any grounding faults in the furnace system. The detection system has an early warning function. When the furnace lining becomes thinner to a certain extent, an alarm light will be sounded in advance to remind users to pay attention to the approaching service life of the furnace lining, and to predict the furnace penetration in advance to achieve the goal of safe production. Solve the customer's problem of being unable to start up due to continuous use, and the inability to continue melting due to material in the furnace.

★ Furnace body weighing function: According to customer needs, a weighing system can be installed in the furnace body, and the weight data of the molten iron can be transmitted to the operating platform PLC and displayed through a touch screen, which is convenient and intuitive to reflect the weight of the molten liquid in the furnace body, and facilitate the operator to adjust the composition and arrange the production volume. At the same time, the system can also achieve automatic melting. It can automatically control the weighing and transportation of furnace materials according to the formula of each brand's material list, with automatic error compensation, automatic alarm for out of tolerance, printing and recording of ingredient data, high ingredient accuracy and fast speed; Accurate ingredients ensure stable composition of molten iron, providing a strong guarantee for producing high-quality molten iron!

★ Lining pushing out structure: Once the furnace temperature cools below 400 ℃, flip the furnace body to a 90 degree angle, lift the pushing out oil cylinder with a crane, place the oil cylinder connecting flange in the pre designed guide rail at the bottom of the furnace body, start the hydraulic pump station, and easily push out the lining. Reduced work intensity and improved work efficiency.

3、 Hengyang Medium Frequency Electric Furnace Selection Guide

The diversification of products and different cost-effectiveness provide you with more choices and experiences.

1. Development history and comparative selection of intermediate frequency power supply

First generation: KGPS thyristor parallel intermediate frequency power supply

It has been widely used since the 20th century, with low prices and cheap accessories.

High energy consumption, consuming approximately 650 kWh per ton of steel water. Using the method of adjusting DC voltage to regulate power, the power factor is low ≤ 0.90, and there is harmonic interference, which has varying degrees of impact on the operation of reactive power compensation capacitors in the substation.

Second generation: KGCL thyristor series intermediate frequency power supply

It is an upgraded version based on the first generation KGPS parallel intermediate frequency furnace in the past 20 years, which saves about 15% energy compared to the first generation KGPS parallel inverter power supply (with a power consumption of about 550 kWh per ton of molten iron).

Third generation: New energy-saving IGBT module series intermediate frequency power supply

It is a revolutionary and innovative latest energy-saving product that overturns the traditional structure of thyristor intermediate frequency power supply; Adopting IGBT integrated modules (transistors) for frequency and power regulation, and full wave rectification; It is not affected by the amount of furnace material and the thickness of the furnace lining, and maintains a constant power output throughout the entire melting process. The energy-saving IGBT transistor intermediate frequency electric furnace can save 15% -25% energy compared to traditional thyristor intermediate frequency power supply (with a power consumption of about 470 kWh per ton of molten iron).

The main reasons for energy conservation are as follows:

A、 The inverter voltage is high, the current is low, and the line loss is small. This part can save about 15% energy. The energy-saving IGBT transistor intermediate frequency power supply has an inverter voltage of 2800V, while the traditional thyristor intermediate frequency power supply has an inverter voltage of only 750V, which is nearly four times smaller in current and greatly reduces line loss.

B、 The power factor is high, always greater than 0.98, and the reactive power loss is small. This part is 3% -5% more energy-efficient than the thyristor intermediate frequency power supply. Due to the semi controllable rectification method used in the energy-saving IGBT transistor intermediate frequency power supply, the rectification part does not adjust the conduction angle of the thyristor, so the power factor of the entire working process is always greater than 0.98, with little power loss.

IGBT integrated module series intermediate frequency power supply is the latest energy-saving intermediate frequency furnace product recommended by our company.

2. Comparison and selection between steel shell furnace and aluminum shell furnace

|

|

| Steel shell furnace body: Adopting hydraulic station tilting device; The furnace body is welded with high-quality steel structure, which is safer, stronger, and more durable; The sensor is enclosed by a magnetic yoke, covering an area of over 65%. Due to its low magnetic leakage and high efficiency, it saves nearly 5% of energy consumption compared to aluminum shell furnaces. Equipped with a leak proof furnace alarm device, it can predict furnace penetration in advance and achieve the goal of safe production. The steel shell furnace body is designed with two types of dust removal systems: smoking hood and smoking ring, which meet the requirements of environmental impact assessment. Users can choose the configuration according to their needs | Aluminum shell furnace body: Adopting a reducer tilting furnace device; The furnace body is made of alloy aluminum sand casting; Low cost, easy to maintain, and convenient to observe. The disadvantage is that the efficiency, service life, and safety are relatively low, and electromagnetic radiation is not shielded. Due to the lack of smoking and dust removal devices in aluminum shell furnaces, some government departments in China have ordered users to replace aluminum shell furnaces with steel shell furnaces |

Tag list: Cast steel melting furnace

Regarding HENG YANG

Induction melting furnace: mainly used for the melting of metals and all kinds of alloys , such as steel, copper, aluminum alloys, etc. is Applications in the casting, steelmaking industry.

VIM-Vacuum Induction Melting Furnace: Melting materials of Ni-based special steel、 precision alloy, super-alloys, magnetic material, Powder Metallurgy in a vacuum environment or protective atmosphere.

Metal powder equipment: HengYang can customize a complete set of powder metallurgy production line for you and provide mature and advanced powder spraying technologyrse,

Our technology is constantly updated,and we have strong R&D capabilities.Hope different price-performance ratios can let you have more more choices and varies experiences.

Frequently Asked Questions

What technical support is provided for overseas client visits?

How do you ensure after-sales response efficiency for international clients?

What key subsystems are included in your custom PM production lines?

What are the technical barriers of your VIM furnaces for superalloy melting?

What are Hengyang's core competencies as a metal smelting equipment provider?

Category:

Parameters

GET FREE CONSULTANCY

A Leader in the Casting industry To Manufacture World-class Products!

Hengyang is a high-tech private enterprise integrating R&D, production, and marketing of induction heating equipment including intermediate frequency furnace. We are also one of the largest leading intermediate frequency furnace manufacturers in China.

Scan the code to add WeChat

Contact: Ashley Huang

Email: service3@hyfurnace.com

Mobile/Whatsapp/Wechat: +8618098177996

Contact: Linda

Email: service1@hyfurnace.com

Mobile/Whatsapp/Wechat: +8613318393785

Scan the code to add WeChat

Contact: Mr. Deng

Mobile/Whatsapp/Wechat: +8618923178785

Quick links

Copyright©2025 Hengyang Furnace Manufacturing Co.,Ltd