Product Category

PRODUCTS

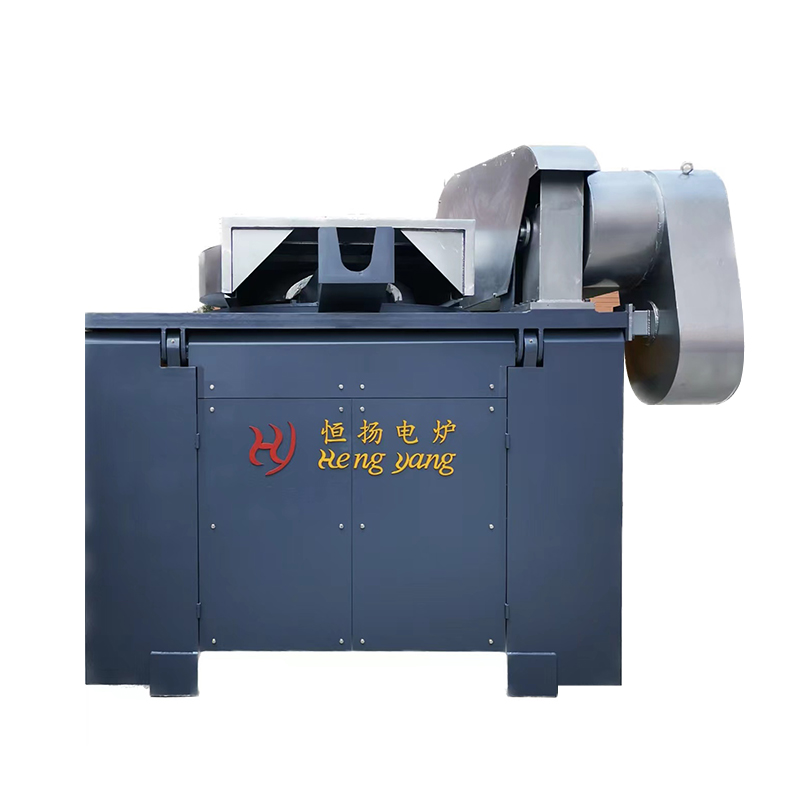

Induction Melting Furnace

Overview and Application

IF Furnace is the device to convert three phase power current into single phase power current by electromagnetic induction to make metal produce eddy current loss and finally achieve the goal of heating and melting. IF Furnace is also applicable to melting and heating of steel, copper, aluminium and other ferrous or nonferrous metal it's widely used in casting and melting industries.

Foshan HengYang fumace Manufacturing Co.,Ltd--is the largest manufacture of medium frequency furmace in Guangdong Province,China. HengYang company products : New KGCl series inverter IF power supply,common KGPS IF Parallel power supply; The new KGcl series which has one power supply with two fumace body work at the sametime (one for smelting, one for heating preservation). with the capability to provide all equipment of production line including smelting system, cooling system, dust removal system, and automatic feeding and pouring system. We not only provide high quality and reliable products, but also free of charge to provide customers with relatedcrafts applications , technology and training on Casting and Heating Treatment industry field. There is independent after-sales department to carry out regular follow-up service for the products which directly solve the users' actual production problems and make customers far away from worries.

Intelligent Circuit Breaker

Intelligent protection function: When the medium frequency power supply equipment is in the state of overload, short circuit, under voltage and single phase grounding fault, the breaker can protect the safety of transformer through the instantaneous trip current and improve power supply reliability. Being designed with a communication interface, the circuit breaker is able to meet the requirements of the control center and automation system.

Furnace Anti-fall Protection Device

The furnace body is equipped with an anti-fall protection device. During the process of tilting the furnace, the anti-falling protective hood will be automatically raised to form a protective barrier to prevent the personnel from falling, so as to ensure the safety of the operator on the furnace platform. The protection device is integrated with the furnace body, and the structure is exquisite. It achieves the multiple combinations of firmness, aesthetics, and safety.

Lining Detection (Leak-proof Alarm Function of the Furnace)

Hengyang has a special dual leak-proof furnace alarm function. By using a differential current mode and DC Infusion, we can detect the leaking situation. It provides a very reliable leakage furnace and a full range of quick protection for any ground fault. The detection system has an early warning function. When the lining is thinned to a certain degree, a warning light will be generated in advance to alert the user that the life of the lining will come to an end and that the furnace can be predicted in advance to achieve the goal of safe production.

Water Protection System

Water flow temperature detector is installed at each branch inlet. Once the equipment is lack of water or at an over-high temperature, the system will help the machine alarm and cut off power supply automatically, which can prevent damage caused by the lack of water and ensure the safe operation of the intermediate frequency electric furnace.

Efficient

A single furnace melts in just 40 minutes! The power consistently maintains peak performance above 0.96.

Throughout the process – from smelting to finished products – the intermediate frequency power delivers maximum output without manual adjustment, regardless of operational conditions.

Energy Saving

Our furnace operates at an ultra-low energy consumption of approximately 530 kWh per ton of molten iron, saving up to 20% electricity compared to conventional parallel inverter power sources.

Harmonic Motion

The full-wave bridge rectifier power supply series achieves international harmonic current/voltage limits. Operating with continuous diode conduction throughout the cycle, it maintains THD control to prevent grid pollution and ensures compatibility with substation reactive power compensation capacitors.

Coil

Optimized Induction Coil Design Significantly Reduces Losses

Induction coil loss in medium-frequency furnaces accounts for 25% of total power consumption, making scientifically rational coil design critical. We utilize premium TU1 oxygen-free copper with high-silver brazed joints, delivering superior conductivity and minimized losses. Insulation spacers implanted between turns ensure optimal turn spacing, enhancing insulation performance while maximizing thermal efficiency.

Stabilization

High standard of component selection ensures the stability of the equipment.

✅ Imported high-pressure carbon-free hose and 304 stainless steel clamp: durable!

✅ Optical fiber transmission inverter trigger pulse signal plate: a strong ability of anti-interference and stable operation!

✅ The high-quality heavy platform Thyristor, square-type water cooling radiator (Hengyang Patent No.): more convenient!

✅ Customized capacitor: horizontal structure, safer insulation outer shell. The high-strength magnesium-aluminum alloy makes the product more anti-corrosion and more durable.

✅ Conductive copper bar: Large and thick copper can reduce heat loss and save energy! With a copper sandblasted surface and anti-oxidation coating, the contact surface of the copper bar is more conductive and the color does not fade which makes the product more beautiful!

✅ Isolation (exchange) switch: when the furnace is replaced or overhauled, it is possible to control the power failure of one furnace without affecting the normal operation of the other furnace. The design is humanized.

✅ Plate heat exchange system (Hengyang Patent No.): It can ensure the cooling water temperature in the equipment and prevent the external hard water from entering the power, which can minimize the equipment failure.

Environmental protection

We adopt environmental-friendly dust-removal cover and comply with the national environmental assessment requirements.

Furnace uses whirlwind, side suction heat- preservation furnace cover, and dust hood (ring) to make certain air absorb the dust and waste gas generated in smelting, improving the effect of exhaust emissions and meeting the requirements of environmental impact assessment design.

Comparasion between new energy saving KGCL and common KGPS

New Energy-saving KGCL Thyristor Series Medium FrequencyPower Supply

Using full-wave rectifier power supply series, in the whole workingprocess of the rectifier is always in a state of full open (equivalentto a diode rectifier), do not produce higher harmonic, basic nopollution to power network, does not affect the operation ofsubstation reactive power compensation capacitor.Achieveinternational harmonic current and voltage allowable value!Compared with common parallel inverter power energy savingabout 20%.(cast iron about 530 kwh/T)

KGCL series inverter medium frequency power supply is themost new energy-saving medium frequency furnace productrecommended by our company.

Common KGPS Thyristor Parallel Intermediate Frequency Power Supply

Advantage: it is the most widely used in thepast few decades.cheap, easy maintenance,reasonable price of spare parts.

Disadvantage : high energy consumption,electric consumption of steel water about650 Kwh/Ton.By adjusting the power of dcvoltage, the power factor is low (less than0.90), and there is harmonic interference,which has different influence on the operationof reactive power compensation capacitor.

Comparison between steel shell and aluminum shell furnace body

Steel Shell Furnace

Steel shell furnace : Adopt the hydraulic station tilting furnace device, the furnace body adopts high quality steel structure welding, safer, firm, durable; The sensor is enclosed with a magnetic yoke, covering an area is over 65%. Because of the leakage is small, the efficiency is high, compared with the aluminum shell furnace save nearly 5% energy consumption. It is equipped with an alarm device for preventing leakage, which can be predicted in advance to achieve safe production.

Steel shell furnace has two kinds of dust removal systems, which meet the requirements of environmental protection, and the user can choose the configuration according to their requirement.

Aluminum Shell Furnace

Aluminum shell furnace: Adopt reducer tilting furnace device; The furnace body is made of alloy aluminum casting. Inexpensive, easy to maintain, easy to observe. The disadvantage is that electromagnetic radiation is unshielded, efficiency and service life are relatively low.

Closed Water Cooling System

The core of ciosed cooling tower adopts copper coil with high heat exchange efficiency, allowing working fluid (purewater or other liquids) to flow through the pipes and cooling the external spray water for natural heat exchange.With a small Floor area,no need to build cooling pools, well as install water pumps and pipelines. This avoids the needfor huge and complex water cooling and saves plant land, Users only need to connect to the inlet and outlet, run onthe power supply for long periods of time, basically without maintenance.The fully-enclosed soft water cooling system has high cooling efficiency, stable water temperature, and is not easy togenerate scale, and eliminates blockage caused by debris Can greatly reduce fault rate of iF equipment .greatly prolongservice life.

Operation Diagram

Furnace Dust Removal System

Bag-type dust collector is kind of dust removal equipment with high efficient, reliable and convenient , it is a matureand advanced structure bag filter which is widely promoted in domestic, which has a good effect. can be used tofilter the wind speed and ensure high dust removal efficiency under the same pressure condition and other dustremover. The filter bag adopts the external filtration method, and it is not necessary to enter the dust collector whenchanging the bag. The structure is compact, reasonable and maintenance work is less.

Furnace Transformer

Furnace transformer means power supply transformerfor industrial electric furnace melting and specialtransformer designed according to workingcharacteristics and operation modes ofvarious fumacesThe special transformer of medium frequency furnaceis characterized by: according to the national industrystandard and according to the technology of differentelectric furnace design, energy conservation andenvironmental protection, anti-harmonics, no heat,anti-short circuit, owerload ability. Its comprised of twotypes: with or without reactor, also have the structureof big impedance and small impedance to meet theneed of customers . Compared with the comentionalcapacity transformer, the smelting time is reduced byabout 15%,and the power consumption of tons isreduced by about 70 degrees.

Automatic Feeder

Vibration/hydraulic loading truck, ladle/molten steel, the use of loading truck increases the efficiency and safety of feedingoperation, and reduces manual operation. ntelligent feeding system, stable and reliable, easy to maintain, With ful-automatic.semi-automatic, manual operation mode.in addition to the effect of environmental dust removal, the use of ladle/iron andwater trucks reduces the probability of steel accidents, such as leakage of steel, and makes the medium frequency furnacesteel more secure.

Electromagnetic Batching System

Electric Batching $ystem: it is used for the distribution of magnetic metal charge, and there are two ways to control automaticbatching and manual mixing. The microcomputer automatic batching can ensure the stable and accurate iron water quality.reduce the adjusting time and improve casting quality. lt can also be equipped with transportation and transfer mechanism.Electric Loading and Unloading System used for metallurgy, machinery factory cast steel, cast iron workshop electric furnacecupola furmace after lifting pig iron, material Recycling, scrap and other bulk metal charge and steel plate, can also be used forcasting sand cleaning, casting suction hanging occasion., The labor intensity of the workers is greatly reduced, automatic preciseingredients are made possible, and the economic benefits are obvious.

IF Power Supply Technology

Energy-efficient KGCL series one-Drag-two (one furnace smelting andanother one heat-preservation) dual power supply design.

KGCL medium frequency series power supply can realize single power supply,double power supply and Multi-power supply configuration.

The latest model " one-drag-two If induction Melting furnace” is with one set of if power supply with two furnace bodyworking at the same time.Equipment utilization rates 100%, only by adjusting the power knob (or digital operation panel).can achieve The total power of the intermediate frequency power supply can be distributed between the two furnaces, alsoachieve one furnace to melt another furnace preserve heat, Large castings can be made in one - time casting or continyoussupply of molten iron in the production line. continuous smelting mode has greatly improved the production capacity, energy saving and practicability, Our product is widely accepted and loved by customers all over the world.

Advanced Computer Smelting Management System

Smelting management computer, digital maincontrol board, PLC and other equipment constitute a network system. It can be managed in the office by extension of the switch. WithEthernet port, USB interface and unique IP address, data acquisition, transmission and monitoring can be realized anywhere in the world, providing remote diagnosis for you,andquickly and timely troubleshooting,

Full Digital on-site Smelting Control System

Automatic constant temperature, automatic furnace drying, power distribution display,intelligent smelting management, display and storage of fault information etc.This equipment can be control by Fully automatic, including PLC programmable controller and HMI man-machine interface or industrial control computer system and industrial control configuration software and various sensors etc., can be achieved with foundry equipment and operating configuration, and join various tools, including remote displays,temperature measuring instrument, thermal analyzer,spectrometer, demand controller and large screen display etc. more convenient and security!

Remote Operating Table

If the power supply cabinet placed in the basement when the remote console placed on the furnace, can carry out other functions ofstart, stop and reset operation of medium frequency power supply. The remote console is equipped with a large-sized touch screen、 PLC and the human-machine interface are composed of an on-site smelting manager that is convenient operation features include: automatic furnace drying, cold start, fault diagnosis, fault information display and storage, operation information, system status display.

Fault Detection (protection) Display

The real-time tracking and protection of the running equipment can detect the abnormal value of load short circuit, over-current, over-pressure,water pressure and high water temperature. It will timely feedback to the control system, and achieve automatic shutdown . Inaddition, the damage of Thyristor, compensation capacitor,voltage transformer and other components will automatically stop and light outthe corresponding indicator.

IF Furnace Technology

Whole furnace includes: open furnace body, induction coil, magnetic yoke.

Configuration includes: anti-falling device, alarm device for leakage protection, quick release mechanism of furnace lining, weighingsystem of furnace body, dust collecting cover or dust collecting ring removal system, furnace Reclining slag structure... !

Open Furnace

The steel frame furnace of HengYang electric furnace is the equipment with high safety, strong, high efficiency,energy saving and convenient maintenance in the induction melting system. The basic design is: the twocylinder with thick wall seamless rectangular steel tube welding into one structure, the furnace body maximumAngle 95 degrees. With vacuum cover (heat preservation cover), the upper end of the induction furnace canbe disassembled to facilitate the replacement of the coil. The unique shock absorber and solid magnetic yokestructure, which combines the advantages of steel cylinder shell and steel tank furnace, is easy for dailymaintain, and the overall structure is simple and secure.

Induction Coil

Assembled by a solid, durable, highly conductive oxygen-free copper tube .The water-cooled coil and theeffective coil are integrally formed by a copper tube without segmentation. The two adjacent copper tubesof the induction coil are strictly insulated and adopt advanced segmentation technology. After the surfaceof the coil is sandblasted, it is used as an insulating coating layer, and then it is poured into an integral bodywith a coil of cement slurry to prevent the coil from damaging the device by discharging iron yoke throughiron chips or dust. The overall structure is strong and there is no deformation problem.

Yoke

①The induction coil is surrounded by a solid oriented yoke,This design isolation eliminates the inductionheating of the furnace body and the metal material outside the furnace.

②The yoke is evenly stressed by the rail bolts and provides maximum holding force to the coil to ensure astrong working life of the lining.

③ Yoke Each cooling water circuit has flow, temperature protection, and temperature display.

④The yoke covers more than 70% of the area and guides and concentrates the induced electromagneticfield into the furnace. Because the magnetic flux leakage is small, the electromagnetic radiation is reducedand the maximum electrical efficiency is obtained.

Two kinds of dust removal systems for the medium frequency: Dust Hood and Dust Ring Dust hood (ring) through a certain fan to absorb dust, waste gas generated in smelting to reach andimprove the effect of exhaust emissions and meet the design requirements of government environmentaldepartment. User can choose different configuration according to their own need.

Dust Removal Hood

Characteristics of Cyclone Type EnvironmentalProtection Dust Cover

The cyclone dust hood has the excellent dustabsorption effect, takes up less space, can be tilted back and forth and any place stops. It is suitable for all automatic feeding and discharging offoundry.

Dust Removal Ring

Side Suction Type Environmental Protection Dust Cover

Side suction type dust removal ring: there is noforward and backward turning mechanism, and theinstallation is simple. It is suitable for those foundrywho cannot use Dust Removal Hood due to somespecial feeding way of semi-automatic or artificialfeeding.

Tilting Furnace Oil Cylinder System

Includes the hydraulic pump station and the tilting table. Designed for tilting full-loaded furnace, it consistsof hydraulic pump and drive motor, emergency pump, motor starter, oil tank, oil return and oil suction filterdevice (with anti-explosion valve device). Through the buttons and the handle on the hydraulic platform,the furnace body can be overturned, stopped and reset.The furnace can be rolled over 95 degrees throughthe push of the hydraulic cylinder and pouring out all the metal liquid, and it also can stop at any positionduring tilting.

Chang-over Switch

Changeover switch is a kind of electric quickswitch used in medium frequency electricfurnace: easy to operate, safe and reliable. It'sconvenient to use, shortens the furnaceswitching time, improves the efficiency, reducesthe labor intensity of the workers, and can easilyachieve the switching of the medium frequencypower supply to the heat-preservation furnaceand the melting furnace, which has greatpracticality.

Fully intelligent automation and humanized functional design

Automatic Thermostatic Function

The range value of the furnace water temperature can be set up in advance, and the automatic thermostat isrealized by the one-click start; Compared with the traditional manual control temperature, the automatic constanttemperature function will save time and trouble, more sensitive and accurate, and the furnace water temperatureis more Easy to control, less oxidation damage, better quality of cast metal components uniform

Automatic Furnace Drying Function

Furnace Drying is a relatively complex and long curve heating process. It is very important to extend the servicelife of the furnace of the intermediate frequency furnace and reduce the production cost and correct dryingfurnace. The company's innovative automatic oven function can preset the time and temperature required bydifferent oven stages according to the furnace temperature requirements of different lining refractories; accordingto the PLC pre-set time and temperature values, one-click start , Automatic matching and stepless regulationof the size of the IF power, control the heating rate, to prevent cracks in the lining, and to achieve the purposeof automatic curve oven. This avoids manual misuse and also reduces the labor time and intensity of workers.

Furnace Leak-Proof Alarm Function

HengYang has special dual leak-proof furnace alarm function, using differential current mode and DC Infusiondouble combination detection. It provides a very reliable leakage furnace and a full range of quick protectionfor any ground fault. The detection system has an early warning function. When the lining is thinned to a certaindegree, a warning light will be given in advance to alert the user that the life of the lining will come to an end,and that the furnace can be predicted in advance to achieve the goal of safe production. Solve the customerproblem because constant use until can' t be turned on, well as there is material inside of the furnace butcan not continue to melt.

Furnace Weighing Function

According to customer requirements, the weighing system can be installed in the furnace, and the weight dataof the molten iron can be transmitted to the operating platform PLC and displayed through the touch screen.The weight of the molten metal in the furnace body can be conveniently and intuitively displayed, facilitatingthe adjustment of the composition and output of the operator arrangement. At the same time, the systemcan also be automated melting. It can automatically control the charge and charge of according to the recipesof various brands, automatic error compensation, automatic over-alarm, printing and recording of materialdata, high precision and high speed of ingredients; the accurate ingredients guarantee the stability of hot metalingredients, and the production of high-quality iron water Provide a strong guarantee!

Lining Out Structure

Once the furnace temperatureis cooled below 400° C, turnthe furnace to 90° degree, liftthe cylinder with a crane, placethe flange of the cylinder on apre-designed rail in the bottomof the furnace, start thehydraulic pump station, andeasily push out the lining.Reduce work intensity andimprove work efficiency.

GET FREE CONSULTANCY

A Leader in the Casting industry To Manufacture World-class Products!

Hengyang is a high-tech private enterprise integrating R&D, production, and marketing of induction heating equipment including intermediate frequency furnace. We are also one of the largest leading intermediate frequency furnace manufacturers in China.

Scan the code to add WeChat

Contact: Ashley Huang

Email: service3@hyfurnace.com

Mobile/Whatsapp/Wechat: +8618098177996

Contact: Linda

Email: service1@hyfurnace.com

Mobile/Whatsapp/Wechat: +8613318393785

Scan the code to add WeChat

Contact: Mr. Deng

Mobile/Whatsapp/Wechat: +8618923178785

Quick links

Copyright©2025 Hengyang Furnace Manufacturing Co.,Ltd