PRODUCTS

HIGH-EFFICIENCY METAL SMELTING EQUIPMENT MANUFACTURER

Applications: Suitable for the smelting of steel, iron, copper and their alloy materials. Primarily used in industries including casting, steelmaking, nickel-based special steels, precision alloys and powder metallurgy.

Intermediate Frequency Furnace | Metal Melting Furnace | Steel Making Furnace | Iron Melting Furnace

Used for melting metals! Widely used in industries such as casting, steelmaking, amorphous, powder metallurgy, etc! Guangdong Hengyang Electric Furnace has been specializing in the production of medium frequency furnaces for 23 years since 1999;

Consulting

Consulting

Used for melting metals! Widely used in industries such as casting, steelmaking, amorphous, powder metallurgy, etc! Excellent products, crafted with ingenuity! High end electric furnace, manufactured by Hengyang Intelligence!

Consulting

Consulting

Induction furnace for cast iron

Medium frequency furnace is a frequency conversion device that converts three-phase power frequency current into single-phase medium frequency current. It induces eddy current loss in metal through electromagnetic field induction, achieving the purpose of heating and melting. The product is used for melting or heating metals such as steel, copper, aluminum, and amorphous magnetic materials; Mainly used in industries such as casting, steelmaking, amorphous, new materials, powder metallurgy, etc!

Consulting

Consulting

Induction melting furnace / Cast steel melting furnace

Intermediate frequency furnace products are used for melting or heating metals such as steel, copper, aluminum, and amorphous magnetic materials; Mainly used in industries such as casting, steelmaking, amorphous, new materials, powder metallurgy, etc!

Consulting

Consulting

New Energy-Saving Induction Melting Furnace

The product is used for melting metals; Widely used in casting Steelmaking Amorphous Powder metallurgy and other industries! Efficient and energy-saving! Low pollution • meets the requirements of environmental impact assessment!

Consulting

Consulting

Payment: T/T,L/C, Western Union,D/P, D/D,Money Place of Origin: Guangdong,China Brand: Hengyang Certification: CE,ISO Delivery Time: 10-30 days after received the deposit Delivery Port: Foshan,Guangzhou,Shenzhenetc.

Consulting

Consulting

Heating Equipment For Steel Billets Before Rolling, Heating Of Square Billet Fittings

Used for metal materials in rolling, forging before the penetration of heat treatment process. It has the advantages of uniform temperature and easy control, high degree of automation.

Consulting

Consulting

MOQ: 1 Payment: T/T,L/C, Western Union,D/P, D/D,Money Place of Origin: Guangdong,China Brand: Hengyang Certification: CE,ISO Delivery Time: 10-30 days after received the deposit Delivery Port: Foshan,Guangzhou,Shenzhen etc.

Consulting

Consulting

Professional Continuous Casting Machine

MOQ: 1 Payment: T/T,L/C, Western Union,D/P, D/D,Money Place of Origin: Guangdong,China Brand: Hengyang Certification: CE,ISO Delivery Time: 10-30 days after received the deposit Delivery Port: Foshan,Guangzhou,Shenzhen etc.

Consulting

Consulting

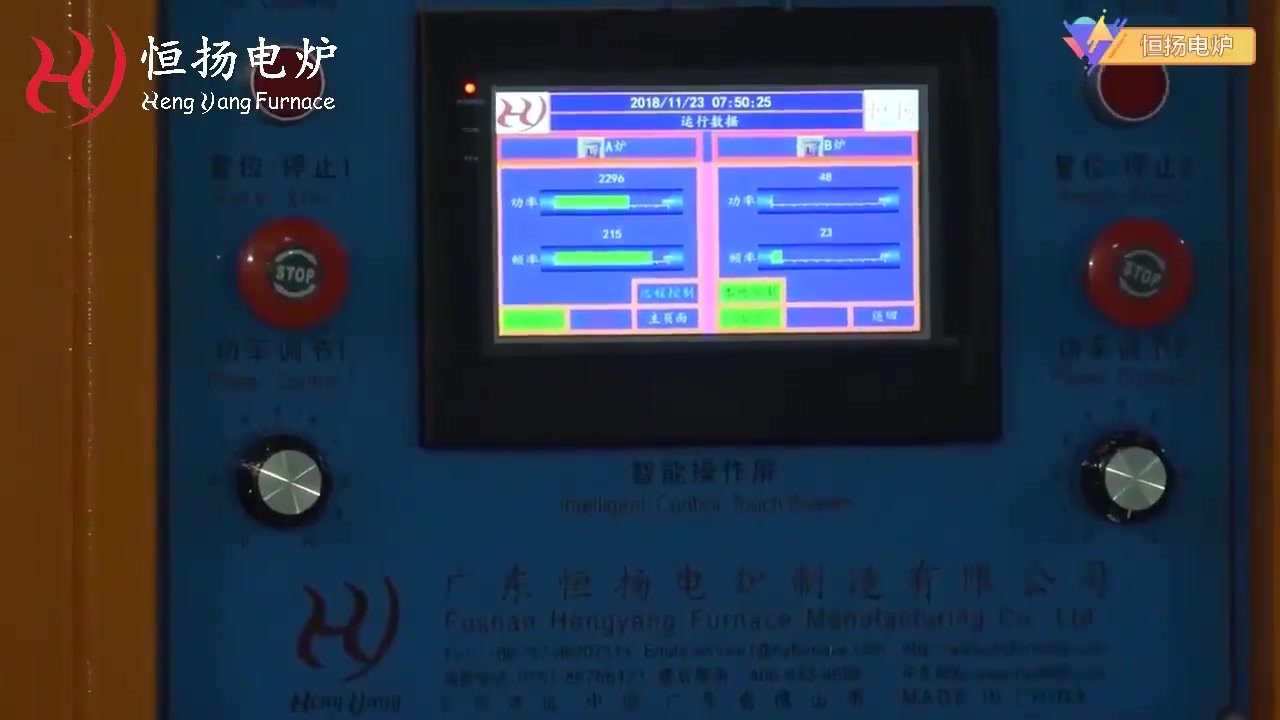

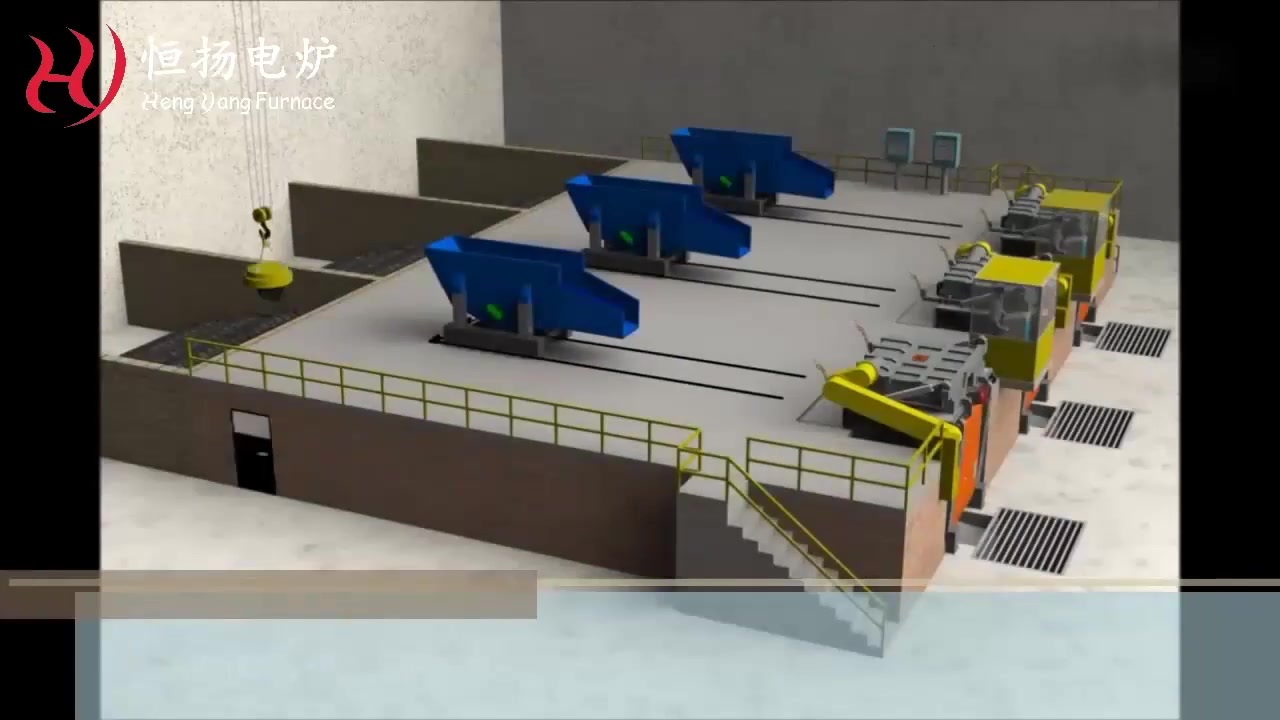

VIDEO

FREQUENCY FURNACES AT HENGYANG ELECTRIC FURNACE

Industry-Leading Technology in Action: CE-Certified Equipment, High Efficiency, and User-Centric Design – Unveiling the Making of High-Performance, Cost-Effective Electric Furnaces

COMPANY

China Hengyang Furnace Manufacturing Co., Ltd.

Was established in 1999. located in Guangzhou city,China.We are a high-tech private enterprise integrating production, R&D and marketing of metal smelting and metal powders equipment.

⭕Induction Melting Furnace: Melts metals/alloys (steel, copper, aluminum) for casting and steelmaking industries.

⭕VIM Vacuum Induction Furnace: Processes Ni-based alloys, super-alloys, magnetic materials, and powder metallurgy under vacuum/protective atmospheres.

⭕Metal Powder Equipment: Customized powder metallurgy production lines with advanced spraying technology.

⭕R&D Strength: Continuous innovation ensures cutting-edge technology and cost-effective solutions.

Established in 1999

Manufacturing base

Export countries

CERTIFICATE

★ State Intellectual Property Office of the P.R.C ★ ISO9001 International Quality Management System Certification ★ The European Union CE certificate authority certification

ZL 2016 2 0875238.3 Patent Certificate

ZL 2016 2 0874851.3 Patent Certificate

ZL 2016 2 0874819.5 Patent Certificate

ISO Certificate for Intermedium Frquency Induction Furnace

CTK-CE Certificate for Intermedium Frquency Induction Furnace

Hengyang Electric Furnace - Quality Reliable Products - Certificate

ADVANTAGE

We are a high-tech private enterprise integrating production, R&D and marketing of metal smelting and metal powders equipment.

25 Years of Industry Expertise & Technical Accumulation

Established in 1999, we specialize in metal smelting and powder equipment R&D, integrating international advanced technologies. Our products have been validated in over 70 countries, backed by decades of technical refinement and industrial expertise.

Global Certifications & Quality Assurance

Certified by the PRC State Intellectual Property Office, ISO9001, and EU CE standards, we guarantee compliance with global quality benchmarks, delivering stable and reliable equipment performance.

Our Market Positioning and Operation

" Wins Market with high quality instead of low price","Casting industry leading benchmark To build up a world-class pproducts ", Our critical production process and highly competitive energy consumption I can make you feel worth it !

Global Service Network & Hassle-Free Partnership

With overseas branches and proximity to Guangzhou Baiyun Airport, we offer turnkey solutions from R&D to after-sales. Our English-speaking team ensures seamless communication, along with comprehensive logistics support (accommodation, travel, etc.) for international clients.

CAES

OUR CUSTOMERS

Our products have been exported to over 70 countries and regions and we have established our own branches in some western countries. So far, we have been familiar with and respect the culture and customs of various countries and accumulated rich experience in providing customer service for foreigners.

Get a InquiryNEWS

LATEST BLOGS

GET FREE CONSULTANCY

A Leader in the Casting industry To Manufacture World-class Products!

Hengyang is a high-tech private enterprise integrating R&D, production, and marketing of induction heating equipment including intermediate frequency furnace. We are also one of the largest leading intermediate frequency furnace manufacturers in China.

Scan the code to add WeChat

Contact: Ashley Huang

Email: service3@hyfurnace.com

Mobile/Whatsapp/Wechat: +8618098177996

Contact: Linda

Email: service1@hyfurnace.com

Mobile/Whatsapp/Wechat: +8613318393785

Scan the code to add WeChat

Contact: Mr. Deng

Mobile/Whatsapp/Wechat: +8618923178785

Quick links

Copyright©2025 Hengyang Furnace Manufacturing Co.,Ltd

2026-01-20

2026-01-20